China Wholesale Sliding Glass Door Wheels Quotes - Zinc alloy sliding door wheels – Qianchuan

China Wholesale Sliding Glass Door Wheels Quotes - Zinc alloy sliding door wheels – Qianchuan Detail:

Introduction of door wheel

Condor wheel is used at the moving door of balcony, kitchen, dining-room, it is the main component that moves the door, developed buffer to close the action actually, it will door fan hanging, the weight bearing capacity of the door is on wheel, cooperate with condor rail tacit understanding, make the door can move easily. Hanging wheel according to the category of moving door, including wooden door hanging wheel, glass door hanging wheel and folding door hanging wheel, according to the function of the division, there are luxury hanging wheel, ultra-silent hanging wheel, dustproof hanging wheel, etc.. The common load-bearing range of the lifting wheel is 60 to 120 jin

Product Feature

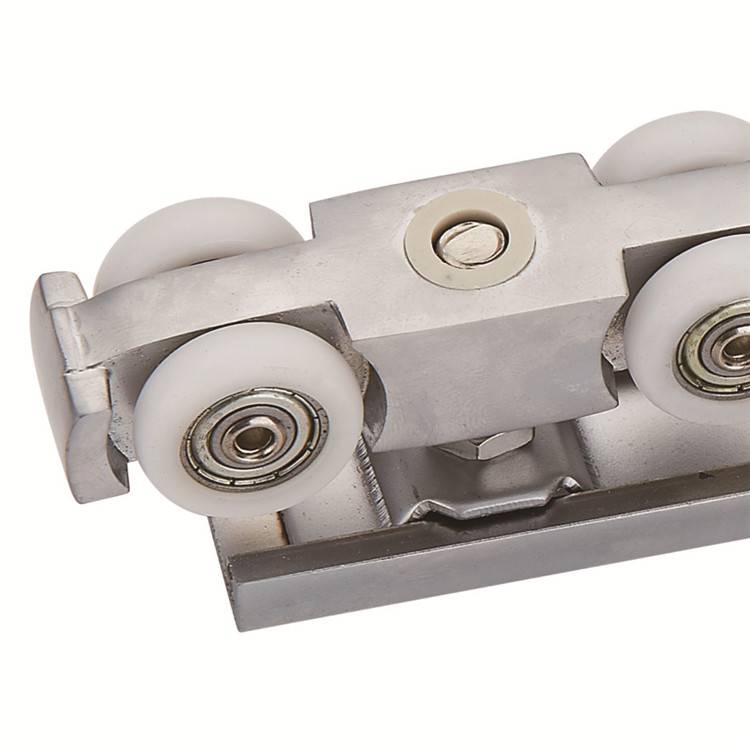

Door wheel advantage:

mute bearing

Built-in more smooth balls, sliding mutely, be powerful

Thicken the fixing iron sheet

Increased thickness of the fixed frame, can be more firmly fixed sliding door

Impact resistant on head part

In order to prevent the strong impact damage the hanging wheel, thickened collision prevention parts

Details show quality

01First

Multi-layer electroplated effectively protect the hanging wheel, increased the door wheel acid resistance, alkali resistance, corrosion resistance.

02 Second

Disassembly accessories

L shape disassembly plug design, quick to install

Easy to remove

03 Third

Smooth bearing hanging wheel

The use the SNK material sliding wheel, bring you a mute experience of live!

Product Image

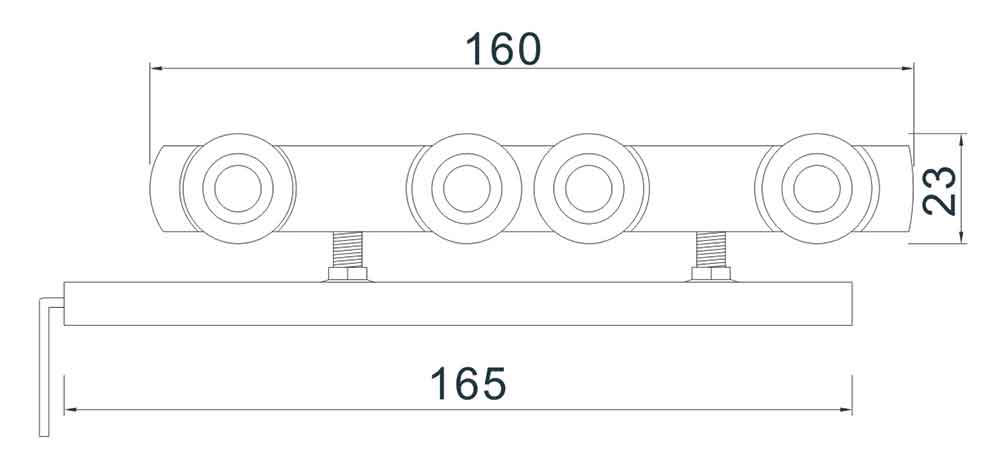

The composition of the door wheel

The sliding hardware of a sliding door consists of two parts, a hanging rail and a door wheel. The hanging rail is the sliding path of the door wheel, which supports and guides the door wheel. The door wheel connects the door leaf and the hanging rail to ensure smooth movement of the door leaf. The door wheel is generally composed of a hanging body, a boom, a stopper, an insert, and an insert seat. [5] In order to prevent the door wheel from swinging, a guide will be added, and the beautiful and high-end door wheel will also be equipped with a decorative cover.

Product Application

Application of door wheel:

The door wheel is used for sliding doors of balconies, kitchens, restaurants, and it is an important part of sliding doors.

一、 Installation method of zinc alloy hanging wheel:

1. First set up the upper hanging wheel part of the sliding door.

2. Pull the top off and insert a 6mm hexagonal wrench into the round hole.

3. If you find it difficult to screw, you can use the short end of the wrench to insert the inner six holes of the screw, and then rotate it.

4. After loosening the screws, pull out the upper pulley in parallel.

5. Then screw in new screws.

6. Push the upper hanging wheel into the gap between the screw cap and the inner wall of the door frame. In order to keep the upper hanging wheel at a certain distance, a piece of cardboard is sandwiched between the upper edge of the door frame and the plane of the upper hanging wheel.

7. Then tighten the screws.

8. The upper pulley is installed. Remove the cardboard.

9. Turn the sliding door over, tree up, insert the screw through the round hole at the bottom, press the lower wheel with your hand, so that the screw hole of the adjustment box can be perpendicular to the screw, and the screw can be easily screwed in. Use a 5mm hexagonal wrench to tighten the screws.

10. After the screw is screwed into the adjustment box, turn it five more times. At this point, the hanging wheels on one side and the lower side of the sliding door have been installed. The other methods of up and down hanging wheels are the same.

11. If the sliding door is uneven after being installed on the hanging rail, you can use a 6mm hexagon wrench to continue adjustment. Rotate clockwise to raise, and turn counterclockwise to lower.

Exhibition

Product detail pictures:

Related Product Guide:

We retain bettering and perfecting our merchandise and service. At the same time, we do the job actively to do research and improvement for China Wholesale Sliding Glass Door Wheels Quotes - Zinc alloy sliding door wheels – Qianchuan , The product will supply to all over the world, such as: Luxembourg, Cambodia, The Swiss, We have now a large share in global market. Our company has strong economic strength and offers excellent sale service. Now we have established faith, friendly, harmonious business relationship with customers in different countries. , such as Indonesia, Myanmar, Indi and other Southeast Asian countries and European, African and Latin American countries.

What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance against the copy of B/L.

What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.